3D printing: how does it work, where to download the templates and how to start?

Have you come up with a design idea for a practical tool or an original decoration? Or are you missing a component that you don't even know where to get? Not only in these situations, 3D printing is what can make your life easier, but also more pleasant. In addition, it is a great activity for DIY and technology enthusiasts. Also, a number of stories from the coronavirus crisis showed us that 3D printer products can even save lives. In this article, we'll tell you everything you need to know to get started with 3D printing.

Basics of 3D printing - CONTENTS

- How does a 3D printer work?

- How to choose a 3D printer: functions, parameters and brands

- What do I need for 3D printing?

- What can be created on a 3D printer and where to get templates/models?

How does a 3D printer work?

3D printing technology is also known as additive manufacturing, which means that the production of products takes place by gradual addition of material. This differs from both CNC machining and milling manufacturing, which, on the contrary, involves the removal of material, for example cutting and shaping the raw material into final product using moulds. Although both of these procedures are very fast and advantageous in large-scale production, they require background, finances, professional staff and a lot of training. Before you even get to create a mould for casting, you can get 3D printed whatever you need. When it comes to production itself, 3D printing is slower, but given the fact that you can print almost immediately, it is an ideal technology for a custom small-scale production or a home improvement design.

We recognize two basic methods of printing 3D objects - FDM (FFF) and SLA. Both principles will be explained below. Importantly, FDM printers are much more widespread and popular. They start at lower prices and allow printing from a very wide range of materials. Although SLA printers do not have these advantages, when it comes to printing accuracy, the ability to realize even small details and create a smooth surface, FDM printers are far behind the SLA printers. Once you understand how both printing technologies work, you'll clearly see why.

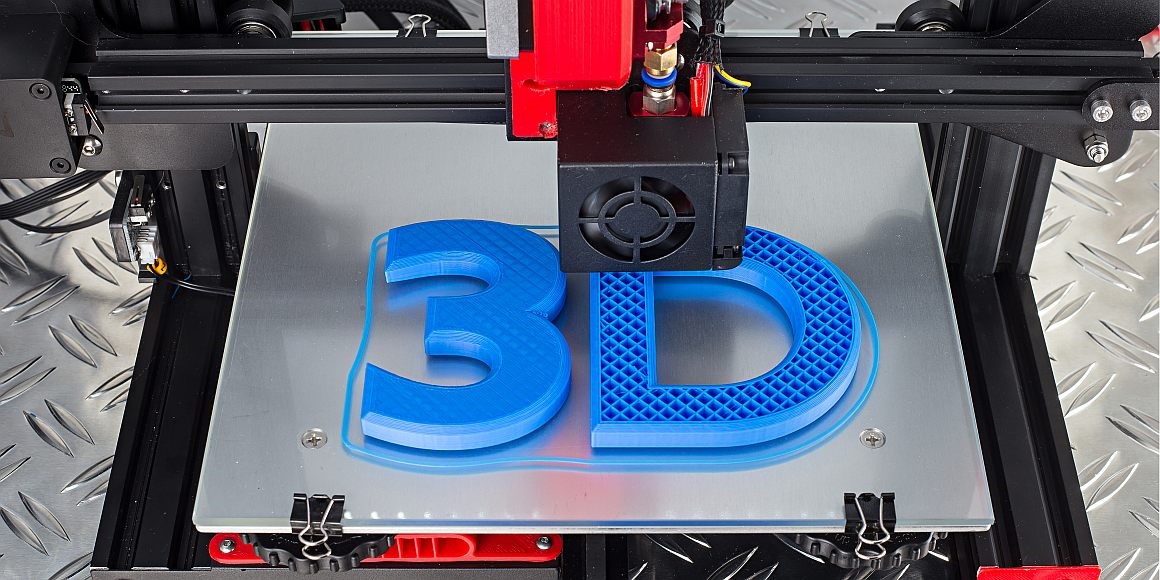

FDM (FFF) 3D printing

FDM stands for Fused Deposition Modeling, but it is a trademark of Stratasys, so even though it is widely used in the 3D printing community, you usually won't find it on the website of individual manufacturers. The correct name of the technology is therefore FFF (Fused Filament Fabrication). This technology is based on melting and controlled distribution of the filament (a string of the printing material).

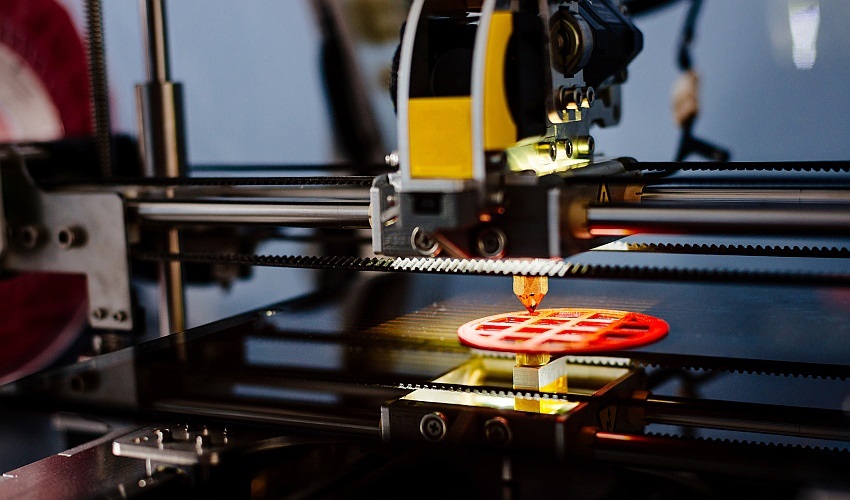

The FFF 3D printing process goes like this: the printing material enters the printer in the form of a strand. In the print head (or extruder) it is melted and forced through a nozzle. The material is applied in layers and transformed into the final product. 3D printing is based on the precise creation of thin layers. The print head travels around the printing surface (bed) according to the instructions created on the basis of the 3D model, and builds up the product in layers from the bottom up.

This printing method is accurate, but depends on the nozzle resolution. At the same time, it causes several side effects, one o them is that the printing material may change its properties during cooling process and unexpectedly shrink (no more then by a few millimeters). Therefore, the print beds are usually heated. Their temperature varies depending on the particular filament, but usually is between 50 and 120°C - the cooling of the material is at least partially controllable. The melting point of the material in the printhead is usually 190 to 280°C, with a maximum of 230°C for standard materials.

However, the advantages of FFF 3D printing predominate. The main advantage is the low acquisition and operating costs. You can buy a standard FFF 3D printer for a few thousands of crowns, you will need to regularly replace just a few parts and you have a choice of many printing materials of various colors and properties. You can print objects that are durable, fragile, solid, flexible, glowing in the dark, conductive, wood imitating and more. In addition, printing with an FFF printer is fast - just prepare or download the model, create instructions for the printer and send it. This makes this type of printer suitable for prototyping, or for anyone who wants to have a 3D printer with practical equipment available for everyday use.

- Low price and operating costs

- Wide selection of filaments with different properties

- Usually faster than SLA printing (not always)

- Lower print accuracy, especially on the vertical axis (compared to SLA)

- Rougher product surface (only at low resolution)

SLA 3D printing (stereolithography)

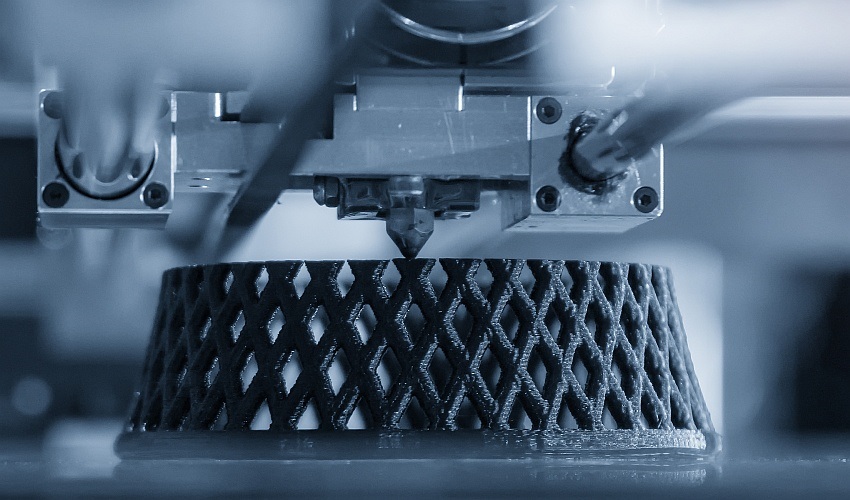

3D printing using the SLA method is based on a completely different principle than FFF. Although it is also an additive production process, it is no longer about melting filament or moving print head giving the product its shape. SLA 3D printing is much more futuristic: it's based on the gradual curing of the photoreactive resin, either by a laser ar a diod.

The process begins by pouring a thin layer of liquid resin into a container, into which the print bed is also immersed. The bottom of the container is then irradiated with precise light from below, which causes the resin to harden and adhere to the print bed. The light is, of course, controlled to affect only those areas that are to form the product layer. When one layer is finished (fully hardened), the print bed rises and the light begins to form a new layer. The height of the layers is in the order of tenths, or even hundreds of millimeters. For the whole time, the printed product is held from above, so if we watch the process in a fast motion, it looks as if the product is gradually pulled out of the resin container.

Even SLA 3D printers differ from each other, most notably by the type of light they use to irradiate the resin. The basic technologies are SLA laser, DLP SLA (Digital Light Processing) and MSLA (mask SLA). The SLA laser gradually irradiates the layer with a single thin laser beam, which makes the process quite long. The DLP SLA uses a projector to irradiate the entire layer at once, so the process is faster. Today, however, the MSLA principle is considered the most advanced one. It works similarly to DLP, but uses an LCD display instead of a projector, often in combination with UV diodes. These serve as a light source and the LCD works as a mask, which shapes the UV backlight light to match the layer that is being printed.

Thanks to the use of light instead of mechanical movements of the print head, SLA 3D printers are significantly more accurate than FFF printers and for the same reason they are also able to create objects with a very smooth surface. So if you plan to print very detailed products often, SLA technology may be just right for you. However, it also has its limitations and these are mainly associated with photoreactive resin. It can't be compared with filaments for FFF printing in terms of price, selection or material properties. Whatever you need to create, you will almost always find the ideal filament. We can't say the same about resin.

- High printing accuracy on all axes

- Very smooth surface of products

- High acquisition and operating costs

- Usually slower printing than FFF/FDM

- Selection and properties of printing materials

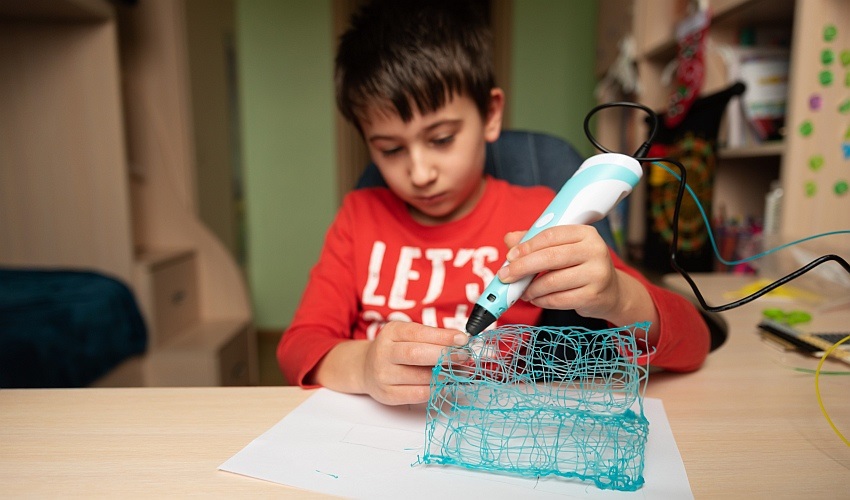

Wondering if you should get a 3D pen and how to choose one? What is it, actually? 3D pens are more about 3D drawing than 3D printing. Instead of printing precisely modeled products, you can get creative with your 3D pen using your own hands. The principle is similar to 3D printers - high-temperature filament melting and its subsequent hardening. However, the automated print head is replaced by manual movement. Therefore, it is mainly the handcraft skill that is needed rather than a technical talent. It is definitely a great tool for everyone, from children through artists to machine developers.

How to choose a 3D printer: functions, parameters and brands

If you have decided to buy a 3D printer, you will definitely want to find out why some models are more expensive than others and what parameters and functions to look out for. There are 3D printers for a few thousands of crowns but also those for tens of thousands. To make the decision whether it makes sense to invest in a more expensive model, or if a basic one will be sufficient, it is important to know at least the basic parameters and functions. So what to look out for when choosing the right one?

- Printing technology: above, we explained how the two main methods of 3D printing work. If you are choosing your first printer, getting a universal FDM/FFF technology might be the best solution.

- Print bed size: This parameter is essential, especially if you want to print large products. At the same time, it is one of the parameters that significantly affect the price of a 3D printer.

- Supported materials: 3D printers are more or less universal. Some models only support certain materials, others can print almost anything. Before you buy a 3D printer, think about what materials you would like to use for printing. Our article How to choose a filament? will help you make a decision. The most common and universal filaments are ABS and PLA.

- Print speed: The ability of a 3D printer to print quickly is undoubtedly important, especially when you need to produce large number of rough prototypes quickly. Higher print speed results in a significant drop in quality. Therefore, the maximum print speed is not always the most important parameter, but it is still advisable to take it into account.

- Print resolution: The accuracy with which a 3D printer can create products is greatly affected by the print resolution. We divide the resolution into horizontal and vertical. Horizontal is defined as the minimum distance that the print head can move along the X and Y axes (for SLA printers, this is the resolution of the projected light). Vertical resolution is represented by the minimum thickness of one layer. FDM printers print layers with a thickness of lower tenths of a millimeter (up to 0.2 mm), SLA's layers have lower hundredths of a millimeter (up to 0.02 mm). The main reason why SLA 3D printers print more accurately than FDM/FFF is the significantly higher resolution.

- Overall printer size: the overall size of the printer is, of course, also important. It determines whether you can have it on the edge of the table next to the computer, or whether you will have to create an extra space for the printer.

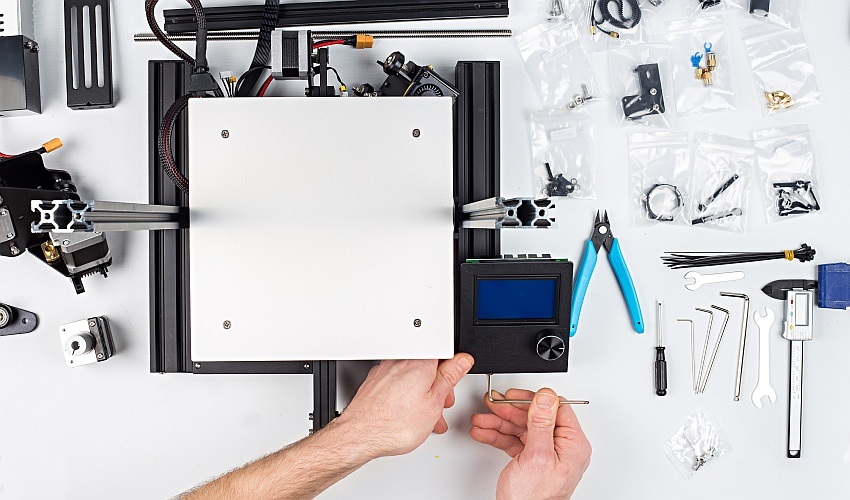

- Construction: 3D printers can be purchased in two different packages - as a DIY kit or fully assembled printer. The DIY kits sometimes vary - for some printers it takes an hour to put them together, for others you will need maximum of tens of minutes. Therefore, always carefully read the product label so that you are not surprised when unpacking. And after unpacking, be sure to read the instructions for the 3D printer. Getting it in the form of a DIY kit is not a bad idea, it will be the first test of your enthusiasm and patience, and you will definitely need both for 3D printing.

There are many manufacturers on the market with 3D printers, so we will briefly talk about the most popular ones.

Prusa

This brand, founded by a Czech do-it-yourself man and inventor Josef Průša, has gained world fame and today produces home printers that can be described as the best 3D printers in the world. All Prusa printers are built as open-source hardware, which means that their design can be easily looked up and downloaded from the Internet, and if you come up with some custom improvements, its implementation will be relatively easy. However, Prusa printers are not among the cheapest and you often have to wait for them, as demand far exceeds supply. But if you want to have a device that leads the way of 3D printing, investing in one of the Prusa 3D printers is definitely worth it.

Creality

If you don't have tens of thousands to buy a printer, but you still want a good quality model, it is best to reach for one of the Creality printers. The models of this brand receive excellent ratings in reviews of professional magazines, along with many awards. Their main advantage is the low price and also the number of pieces in stock. Creality has a relatively high production, which takes place in China, but manages to meet demand, so these 3D printers are usually in stock. So if you want a good quality printer for an affordable price, Creality models may be the right choice for you.

What do I need for 3D printing?

While buying a 3D printer is the biggest and most important step in getting you started printing 3D products, it's not the only one. So what do you need to print on a 3D printer?

- 3D printer: it is clear that you need a 3D printer for 3D printing. We talked about choosing the printer itself in the previous sections of the article.

- 3D models: the models for 3D printing you must either create yourself or download from the Internet. In the last chapter of this article, you'll find out where to find models available for download.

- Computer: you have to get (or create) models and prepare them for 3D printing (without a computer). The computer is also important for updating the printer's firmware and other tasks. Although the hardware may not be particularly powerful, an old computer with less than 4 GB of RAM will not work very well.

- Slicer (3D printing software): When you have a 3D model on your computer, you need to create instructions for the 3D printer. And that's exactly what the software called a slicer is made for. It is called the slicer because it slices the model into layers, which the printer will be gradually building to create the final product. You don't have to pay anything for the slicer, you can download it for free on the website of the printer manufacturer.

- Filament: The building material of FDM/FFF printers is called the filament, which is a thermoplastic formed into strands that are sold by spools. Its diameter is important, but the vast majority of home printers print with filaments with thickness of 1.75 mm. Find out more in our article on filaments for 3D printing .

- Tools: you will need to reach for tools, not only for tightening the parts of the 3D printer, but also, for example, when the product sticks to the print bed so hard that it cannot be removed by hand. For such and other cases, it is advisable to have spatulas , knives , tweezers , screwdrivers and screw keys , pliers , a caliper , a flashlight and a sandpaper at hand.

What can be created on a 3D printer and where to get templates/models?

Rather than listing of products that can be made on a 3D printer, it's easier to make a list of what can't be made on it. The use of 3D printing is limited only by creativity, patience, technical skills and the laws of physics. People make musical instruments, household aids, clothes, models of human body parts or medical supplies on 3D printers. Whatever you can think of, you can design and manufacture yourself, if you have enough knowledge to do so. For modelling, you can use a free software - SketchUp Free, FreeCAD or even Blender and 3D Painting, which you will find on all computers with Windows 10.

Every beginner will certainly appreciate that there are free downloadable templates on the Internet. You don't have to model anything, just download the STL file and prepare it in a for 3D printing in a Slicer. Where to find 3D models? There are many websites on the Internet offering free 3D models. The largest and most famous are those listed below.

3D printing templates for download

- Thingiverse: the largest database of free 3D models with a very active community.

- Cults: database containing verified 3D models for free and others for a fee. In addition to community products, you will also find professional designs here.

- Pinshape: a clear database with most of the content available for free download.

- MyMiniFactory : a comprehensive database of models with proven printability. A large number of models is available free of charge with a possibility of voluntary contribution to the author.

Once you learn to use the 3D printer and work with the models, the door to the world of almost unlimited possibilities will open up to you. You can create whatever comes to your mind. It just takes patience, because errors can happen even in 3D printing.